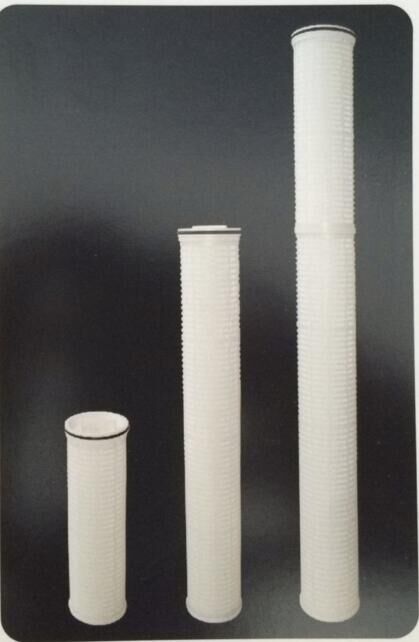

HDP Water Cartridge

General Description

HDP Series High Flow Filter Cartridge is made of diameter 6"(152mm), single open end, without inner core, inside to outside flow direction. Filter body have two types: melt-blown and pleated. And pleated filter is divided into two forms: standard and crescent-shaped. End caps and filter layer using hot-melt welding, no bonding agent, with a wide range of chemical compatibility, can be applied to various fields.

Application:

General Purpose: RO Prefiltration, all kinds process water purification

Industrial: Process fluid, process water, condensed water, coolant, wastewater treatment;

Food and Beverage: Process water;

Petrochemical:Various solvents, chilled water, brine filtration

Power Plant: Supplementary water, condensation water, coolant

Product Features:

*Single cartridge could achieve flow rate 110m3/h

*Filtration systems are 50% smaller than typical size system

*Inside to outside flow direction keeps all of the contamination catched.

Dimensions(nominal)

OD: 6” (152mm)

Length: 20"/40"/60"(same connection size with Pall Ultipleat high flow filter)

Model | Filter Media | Support/Drainage | End Caps | Seals Material |

PP

| Pleated Depth Polypropylene | Polypropylene | Glass Fiber Reinforced Polypropylene |

NBR、EPDM、Viton

|

Melt blown Polypropylene | Glass Fiber Reinforced Polypropylene | |||

GF | Glass Fiber/Polyester | Polyester | Glass Fiber Reinforced Polypropylene |

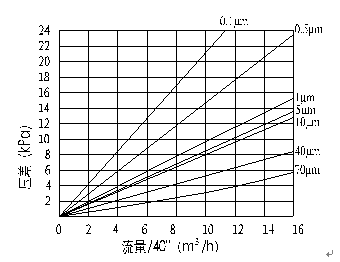

Filter Performance

Micron: 0.1μm, 0.5μm, 1μm, 5μm, 10μm, 15μm , 20μm, 40μm, 70μm

Maximum operating temperature: Pleated/melt-blown pp: 82℃

Pleated glass fiber: 121℃

Maximum operating differential pressure(Inside to outside flow direction):

Pleated/melt-blown pp: 3.44bar@82℃

Pleated glass fiber: 3.44bar@121℃

Suggestion pressure for filter replacement: 2.5Bar@20℃

Suggestion design flow: 40": ≤15m3/h

60": ≤25m3/h

Ordering Information

Type Length(in.) Material Micron(μm) Support Seals

HDP 40 PP 0050 G E

HDP 20 PP: Polypropylene 0010=0.1 B=Outer Belt N=NBR

40 GF: Glass Fiber 0100=1 Y=Outer Belt(crescent-shaped pleated) E= EPDM

60 /Polyester 0500=5 G= PP Outer Cage V=Viton

1000=10 Q=Polyester mesh

1500=15 M=Melt-blown

2000=20

4000=40

7000=70