MPC Testing

The Membrane Patch Colorimetry (MPC) test is a quick, cost-effective way of assessing your oil's varnish potential.

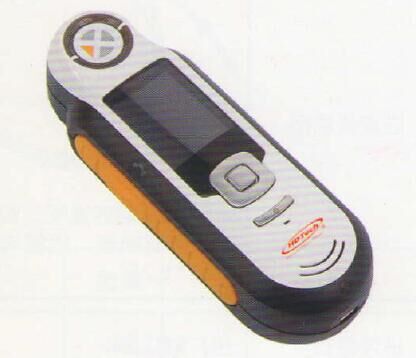

The MPC Color instrument allows real time on-site determination of the condition of your lubricant. Data results are captured and stored in text and audio captions for quick analysis. The MPC Color packs tremendous science into a convenient and extremely accurate package.

MPC is the only ASTM method for determining Varnish Potential

ASTM D7843: Standard Test Method for Measurement of Lubricant Generated Insoluble Color Bodies in In-Service Turbine Oils using Membrane Patch Colorimetry.

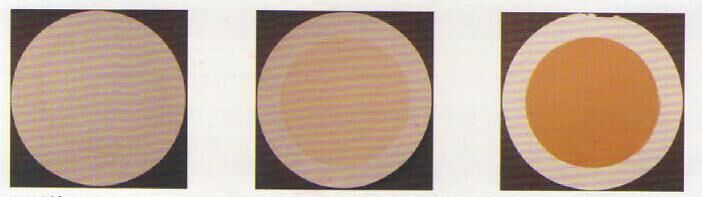

Lubricating oils used in applications such as compressors, turbines and hydraulic systems are prone to reliability and performance problems due to oil deposits like sludge and varnish. MPC test is designed to separate oil degradation products and measure their color. This indicates the likeliness of deposits causing performance problems in your system.

Tremendous Innovation packed into an unassuming package

Some of the features of the MPC Color include:

A surface preview capability with built-in calibration tile

Produces results in 1.8 seconds

Enough memory to store data for up to 350 samples and 20 standards

Connects to your PC via USB connection for ease of data transfer and charging

Reports color values in CIE, the same scale used in ASTM D7843

Includes trend results software called HDTSure©

It provides repeatable and stable measurements that are not affected by urface irregularities

A light weight hand held device making the MPC Color as comfortable in the laboratory or in the plant

Employs independent tri-directional 25 LED light source with 8 different visible illuminations

MPC Color + MPC Patch=HPVLTK

Do you want to test your oil's varnish potential in the lab or on your plant floor? Your choice.

Combining the MPC Color with the MPC Patch allows you to test fluids wherever you'd like. A portable, rugged and compact design provides great flexibility.